Inganda zo gukora Titanium

(1) Coefficient deformasiyo ni nto:

Iki nikintu kigaragara muburyo bwo gutunganya ibikoresho bya titanium. Muburyo bwo gukata, ahantu ho guhurira hagati ya chip nisura ya rake ni nini cyane, kandi gukubita chip kumutwe wigikoresho cyigikoresho ni kinini cyane kuruta icyibikoresho rusange. Kugenda igihe kirekire bizatera kwambara ibikoresho bikomeye, kandi Ubuvanganzo nabwo bubaho mugihe cyo kugenda, byongera ubushyuhe bwigikoresho.

(2) Ubushyuhe bukabije:

Ku ruhande rumwe, coefficente ntoya ya deformasiyo yavuzwe haruguru bizaganisha ku gice cy'ubushyuhe bwiyongera. Ikintu nyamukuru cyubushyuhe bwo hejuru bwo gukata murwego rwo guca titanium ni uko ubushyuhe bwumuriro wa titanium alloy ari buto cyane, kandi uburebure bwihuza hagati ya chip na rake mumaso yigikoresho ni bugufi.

Bitewe nibi bintu, ubushyuhe butangwa mugihe cyo gutema ni Biragoye kubwohereza, kandi ahanini birundanya hafi yisonga ryigikoresho, bigatuma ubushyuhe bwaho buba hejuru cyane.

(3) Ubushyuhe bwumuriro wa titanium alloy ni hasi cyane:

Ubushyuhe butangwa no gukata ntabwo bworoshye. Guhindura inzira ya titanium ni inzira yo guhangayika cyane hamwe ningutu nini, izabyara ubushyuhe bwinshi, kandi ubushyuhe bwinshi butangwa mugihe cyo gutunganya ntibushobora gukwirakwizwa neza. Ku cyuma, ubushyuhe burazamuka cyane, icyuma kiroroha, kandi kwambara ibikoresho byihuta.

Imbaraga zihariye zibicuruzwa bya titanium ni byinshi cyane mubikoresho byubaka. Imbaraga zayo ziragereranywa nicyuma, ariko uburemere bwacyo ni 57% gusa byibyuma. Byongeye kandi, titanium alloys ifite ibiranga uburemere buke bwihariye, imbaraga zumuriro mwinshi, ituze ryiza ryumuriro hamwe no kurwanya ruswa, ariko ibikoresho bya titanium bivanze biragoye kubicamo kandi bifite ubushobozi buke bwo gutunganya. Kubwibyo, uburyo bwo gutsinda ingorane nubushobozi buke bwo gutunganya titanium alloy yamye ari ikibazo cyihutirwa gukemurwa.

Ohereza ubutumwa bwawe kuri twe:

-

Ibikoresho bya Aluminium CNC

-

Urupapuro rwa aluminiyumu

-

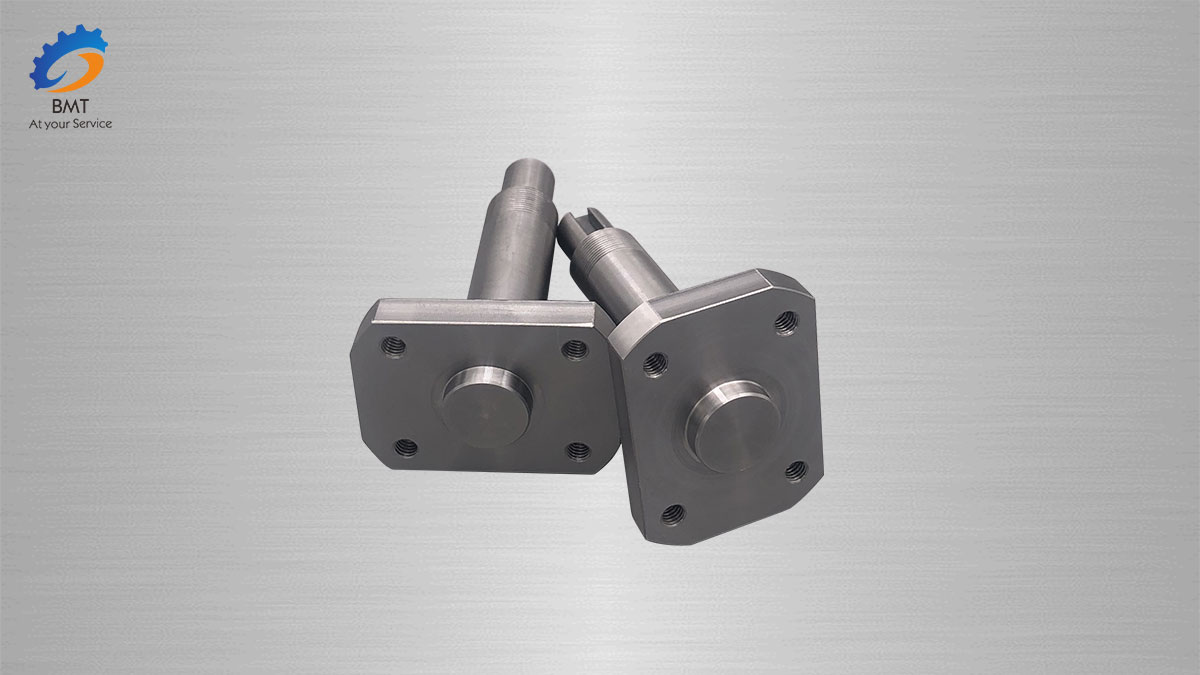

Axis Igice Cyiza Cyimashini CNC

-

Ibice bya CNC Byakozwe mubutaliyani

-

CNC Gukora Ibice bya Aluminium

-

Gukora ibice byimodoka

-

Kwibagirwa Titanium

-

Titanium na Titanium Alloy Ibikoresho

-

Kwibagirwa Titanium na Titanium

-

Titanium na Titanium Alloy Wires

-

Titanium Bars

-

Titanium Imiyoboro idafite imiyoboro / Imiyoboro

-

Titanium Yasuditswe Imiyoboro / Imiyoboro